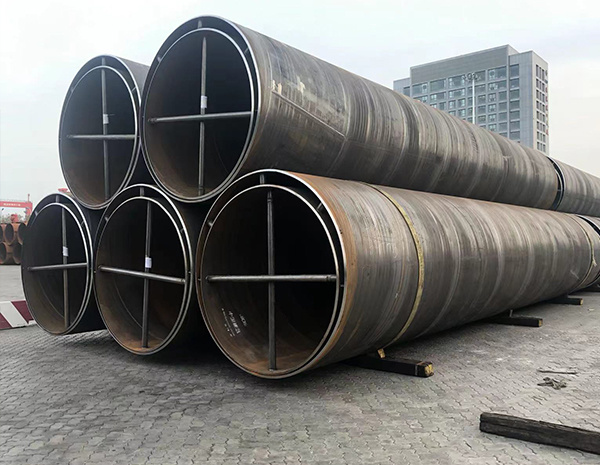

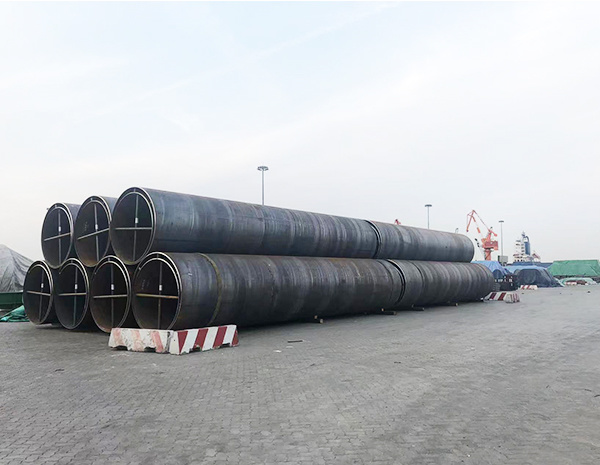

Spiral pipe

Category:

Product Introduction

After the spiral steel pipe rusts, the steel surface is mainly polished by tools such as wire brushes. The cleaning and preheating of the spiral pipe can remove loose or upturned oxide skin, rust, welding slag, etc. The derusting of hand tools can reach Sa2 level, and that of power tools can reach Sa3. If the surface of spiral pipe is firmly attached with iron oxide scale, the derusting effect of tools is not ideal, and the depth of anchor pattern required by anti-corrosion construction cannot be reached.

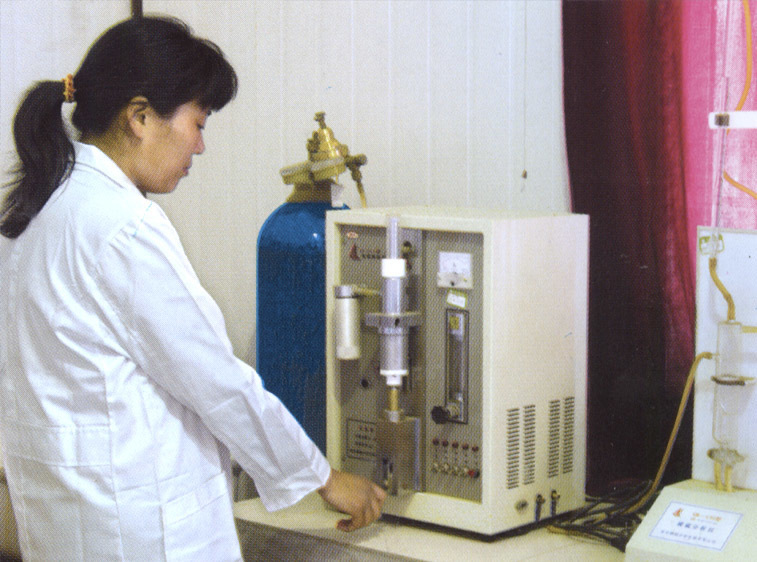

New applications are added on the basis of traditional applications, which makes the use of spiral steel pipes more fruitful, and also reduces the cost of using spiral steel pipes. The radio frequency sensor provides 200 volts, 50 amps of electricity to flow smoothly through the spiral steel tube, heating the test sample by induction.

The spiral tube itself does not become hot, but the experimental sample will have a significant fever. When the heating temperature exceeds the arc melting machine, the radio frequency sensor will provide more control, allowing scientists to adjust the specific composition ratio of the alloy. Spiral steel pipe pressure capacity is strong, good plasticity, easy to weld and processing molding; general low-pressure fluid transportation with spiral seam submerged arc welding spiral steel pipe (SY5037-83), the use of double-sided automatic submerged arc welding or single-sided welding method made for water, gas, air and steam.

Quality Assurance

Key words:

Product Consulting

Related Products