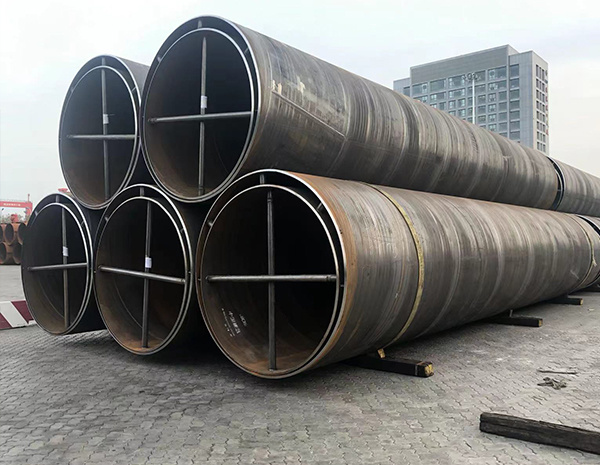

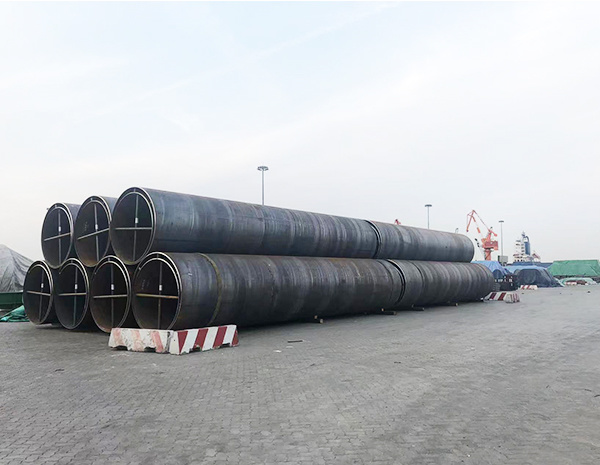

Double-sided submerged arc welded pipe spiral pipe

Category:

Product Introduction

Double-sided submerged arc welded spiral steel pipe has the advantages of high pressure capacity, low resistance, low temperature resistance, corrosion resistance, convenient installation and maintenance, etc., and is more and more welcomed by oil and gas, slurry transportation, urban construction and other industries. The process flow is first carried out. Full board ultrasonic inspection.

1. In the process of steel pipe forming, the steel plate is deformed evenly, the residual stress is small, and the surface is not scratched. The processed steel pipe has greater flexibility in the size and specification range of steel pipe diameter and wall thickness, especially in the production of high-grade thick-walled steel pipes, especially large-diameter thick-walled pipes, which has incomparable advantages over other processes, and can meet users More requirements in steel pipe specifications;

spiral steel pipe

2. The process of pre-welding before internal and external welding (precision welding) is adopted to realize welding at the best position, which is not easy to cause defects such as wrong side, welding deviation and incomplete penetration, and is easy to control welding quality;

3, the overall mechanical expansion, can effectively improve the dimensional accuracy of the steel pipe, and improve the distribution of stress in the steel pipe, so as to avoid damage caused by stress corrosion, while conducive to the field of welding construction;

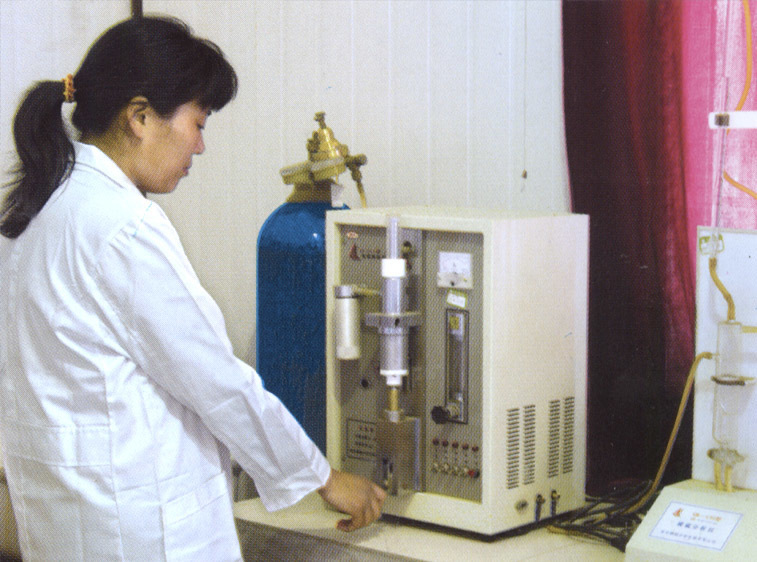

4, 9 100% of the quality inspection of the steel pipe, so that the whole process of steel pipe production are under effective detection and monitoring, effectively ensure the quality of submerged arc welded steel pipe products;

5. All the equipment of the whole production line has the function of networking with the computer data acquisition system to realize the real-time transmission of data. The central control room collects the technical parameters and quality indexes in the production process.

Quality Assurance

Key words:

Product Consulting

Related Products