Spiral pipe

Category:

Product Introduction

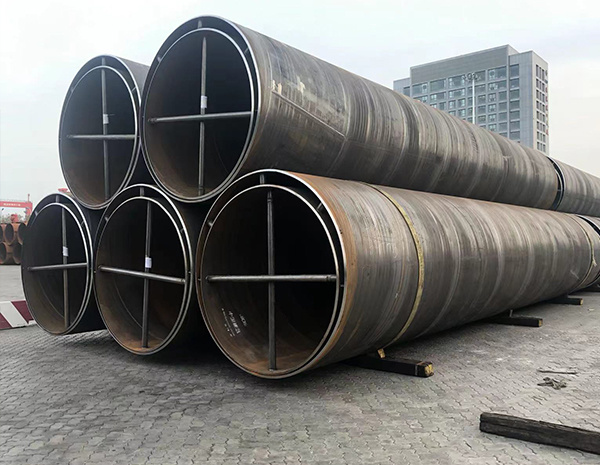

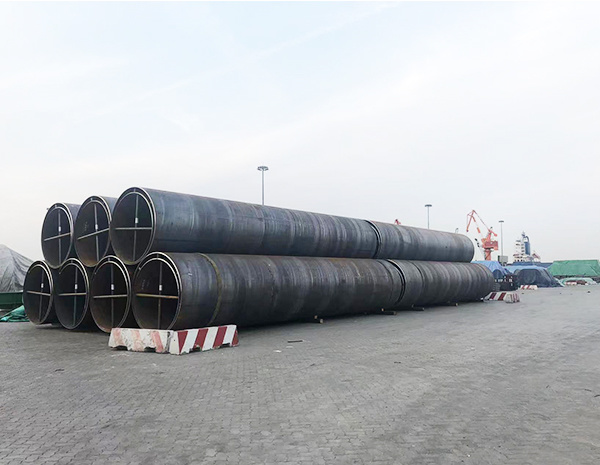

Spiral pipe is mainly used for oil and natural gas pipelines, and its specifications are expressed by outer diameter * wall thickness. The spiral pipe has single-sided welding and double-sided welding. The welded pipe shall ensure that the hydraulic test, the tensile strength and cold bending performance of the weld meet the requirements.

Spiral pipe is also called spiral steel pipe or spiral welded pipe. It is made of low carbon structural steel or low alloy structural steel strip according to a certain spiral angle (called forming angle), and then the pipe seam is welded. It can produce large diameter steel pipe with narrow strip.

Quality Assurance

Key words:

Product Consulting

Related Products