Spiral welded pipe

Category:

Product Introduction

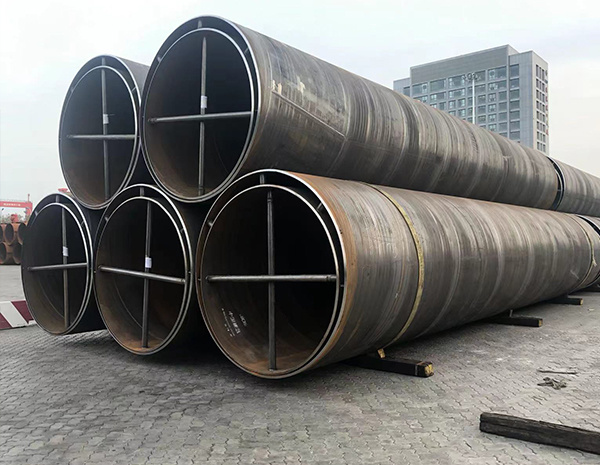

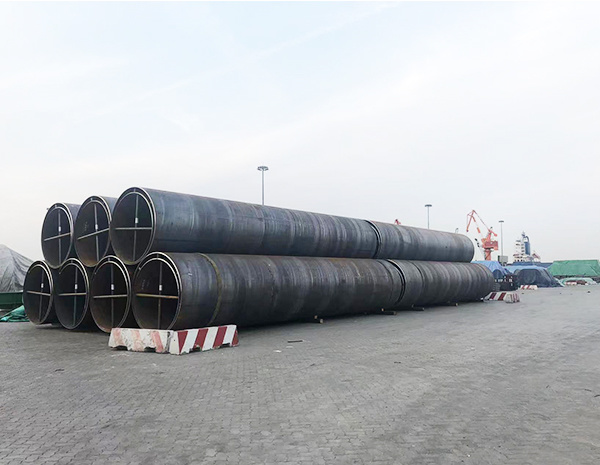

Spiral welded pipe: low carbon carbon structural steel or low alloy structural steel strip is rolled into a tube blank according to a certain spiral angle (called forming angle), and then the pipe seam is welded together. It can produce large diameter steel pipe with narrow strip steel. Its specifications are expressed by outer diameter * wall thickness. The welded pipe shall ensure that the hydraulic test, the tensile strength and cold bending performance of the weld meet the requirements.

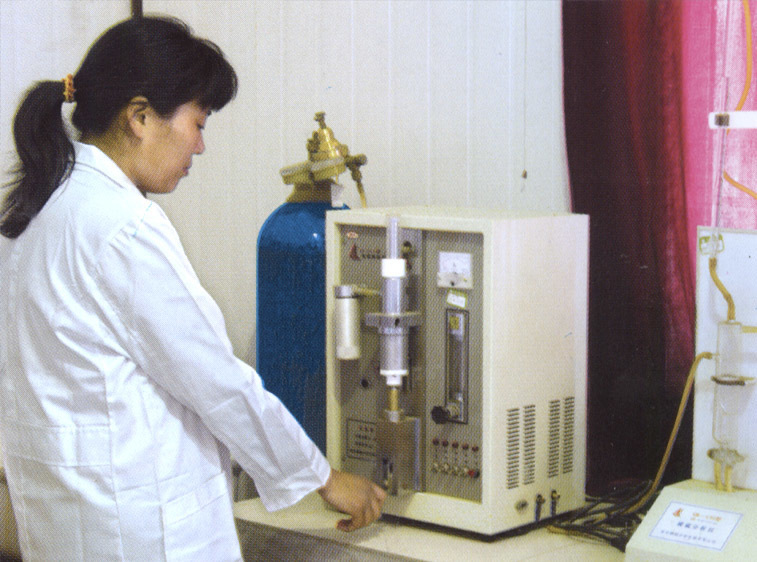

Industrial TV internal inspection equipment: inspect the appearance quality of internal welding seams.

Magnetic particle flaw detector: inspect the near surface defects of large diameter steel pipe.

Ultrasonic automatic continuous flaw detector: inspect the transverse and longitudinal defects of the full-length weld of spiral steel pipe.

Ultrasonic manual flaw detector: re-inspection of large-diameter steel pipe defects, inspection of repair welding seams and quality of welding seams after water pressure.

X-ray automatic flaw detector and industrial television imaging equipment: inspect the internal quality of the full-length weld of spiral steel pipe with a sensitivity of not less than 4%.

X-ray radiography equipment: the original weld and repair weld shall be inspected with a sensitivity of not less than 2%.

2200-ton hydraulic press and microcomputer automatic recording system: check the bearing quality of each large-diameter steel pipe.

Quality Assurance

Key words:

Product Consulting

Related Products