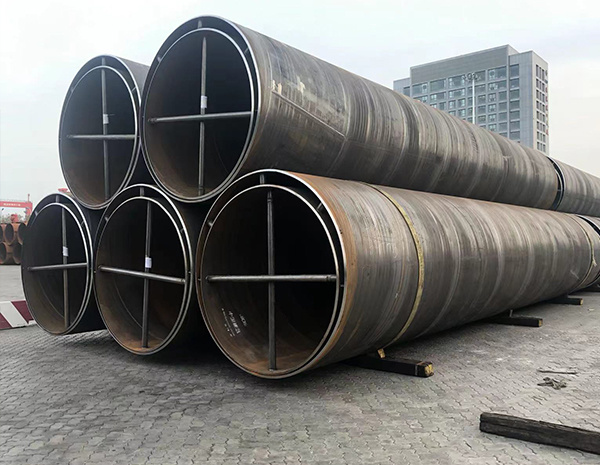

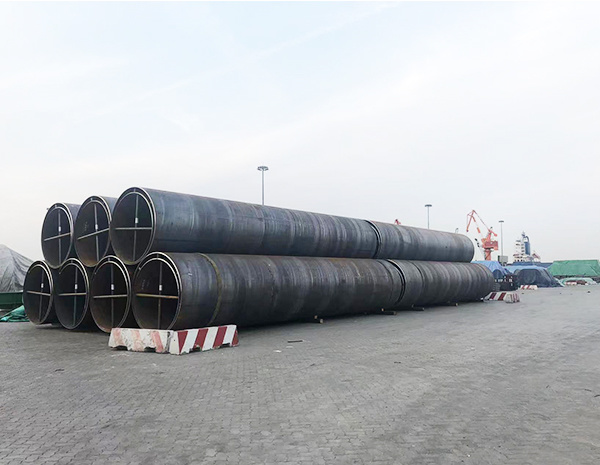

Spiral pipe

Category:

Product Introduction

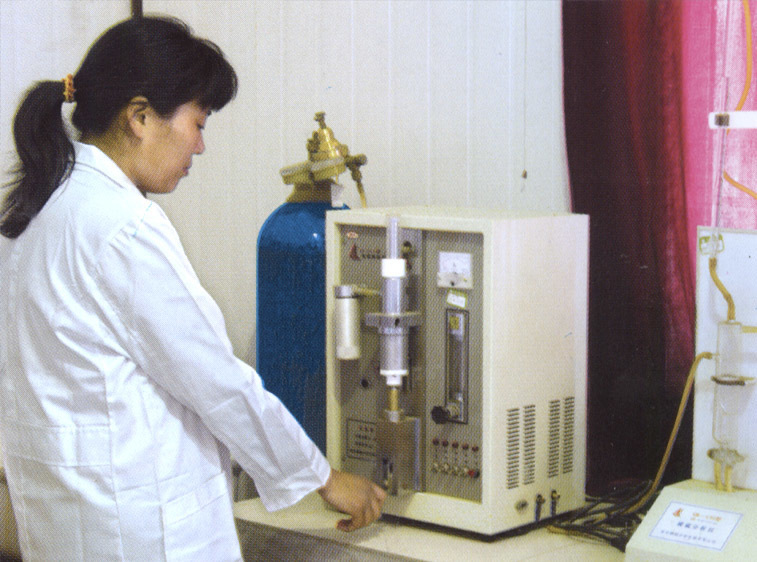

(1) raw materials, namely strip steel coil, welding wire, flux. Before the investment must pass the strict physical and chemical test.

(2) For head-to-tail butt joint of strip steel, single wire or double wire submerged arc welding shall be adopted, and automatic submerged arc welding shall be adopted for repair welding after being rolled into steel pipe.

(3) Before forming, the strip steel is subjected to leveling, trimming, edge planing, surface cleaning and conveying and pre-bending treatment.

(4) The electric contact pressure gauge is used to control the pressure of the pressure cylinder on both sides of the conveyor to ensure the smooth transportation of the strip steel.

(5) Adopt external control or internal control roller forming.

(6) The weld gap control device is used to ensure that the weld gap meets the welding requirements, and the pipe diameter, misalignment and weld gap are strictly controlled.

(7) Both internal welding and external welding adopt American Lincoln welding machine for single-wire or double-wire submerged arc welding, so as to obtain stable welding specifications.

(8) The welded welds are inspected by online continuous ultrasonic automatic flaw detector, which ensures 100% of the non-destructive testing coverage of spiral welds. If there are defects, automatic alarm and spraying marks, production workers according to this at any time to adjust the process parameters, timely elimination of defects.

Quality Assurance

Key words:

Product Consulting

Related Products