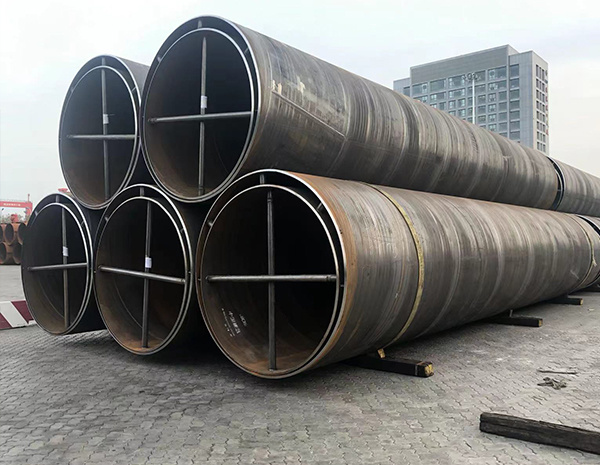

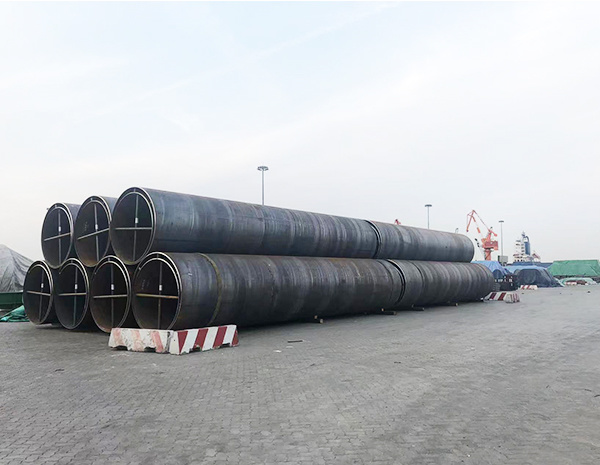

Spiral pipe

Category:

Product Introduction

Spiral steel pipe market demand is both rapid and not chaotic growth trend will not fundamentally change. Whether the spiral steel pipe market can maintain the rapid development of the hub depends on the change of demand. The macro-economy is regulated by the policy level, which will bring a certain slowdown to the market growth rate in the future.

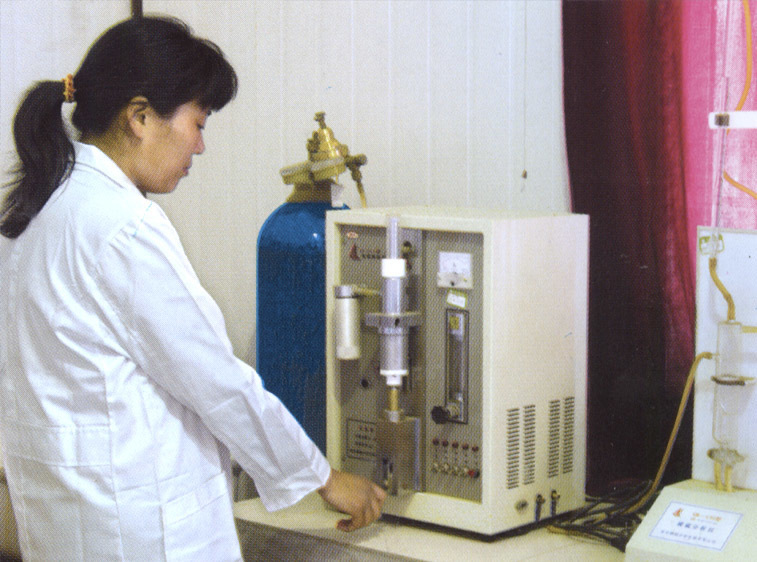

The main raw material is molten iron and scrap steel. The content of sulfur and phosphorus in steel is higher than that of high-quality carbon structural steel. Generally, sulfur is less than or equal to 0.050 and phosphorus is less than or equal to 0.045. The content of other alloying elements brought into the steel from raw materials, such as chromium, nickel and copper, is generally not more than 0.30%. According to the composition and performance requirements, the grades of such steels are Q195,Q215A, B,Q235A, B, C, D,Q255A, B,Q275 and other steel grades.

Quality Assurance

Key words:

Product Consulting

Related Products