Spiral pipe

Category:

Product Introduction

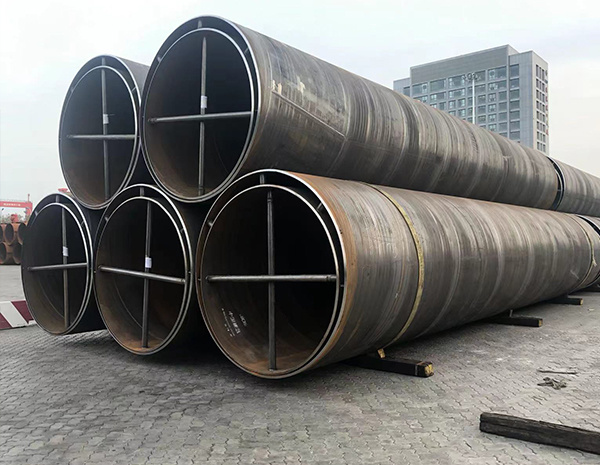

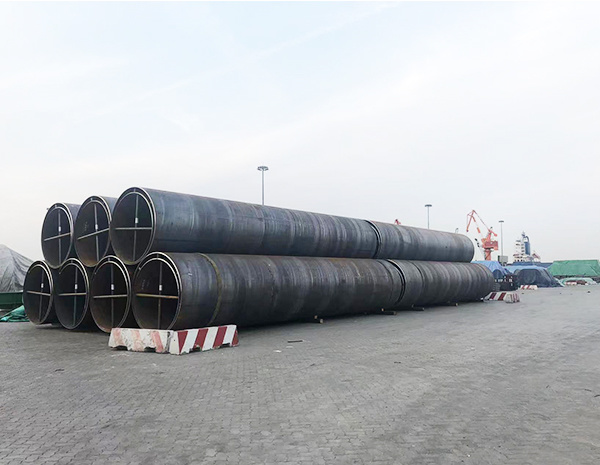

Spiral pipe is also called spiral steel pipe or spiral welded pipe. It is made of low carbon structural steel or low alloy structural steel strip according to a certain spiral angle (called forming angle), and then the pipe seam is welded. It can produce large diameter steel pipe with narrow strip.

Also known as spiral barrel or spiral body. The helical tube has an outer diameter of about 30 nm, an inner diameter of about 10 nm, and an adjacent helical pitch of about 11 nm. The spiral tube is surrounded by six nucleosomes every week, and the H1 histone is located on the inner surface of the spiral tube lumen, which plays an important role in maintaining the structure of the spiral tube. The 10 nm fibers composed of nucleosomes are spiraled to form 30 nm coarse fibers, further compressing the DNA length by a factor of 6.

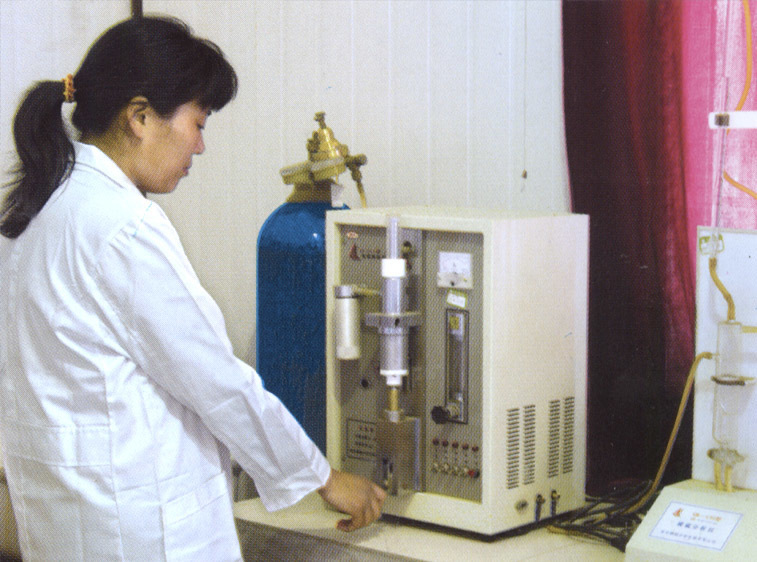

Quality Assurance

Key words:

Product Consulting

Related Products