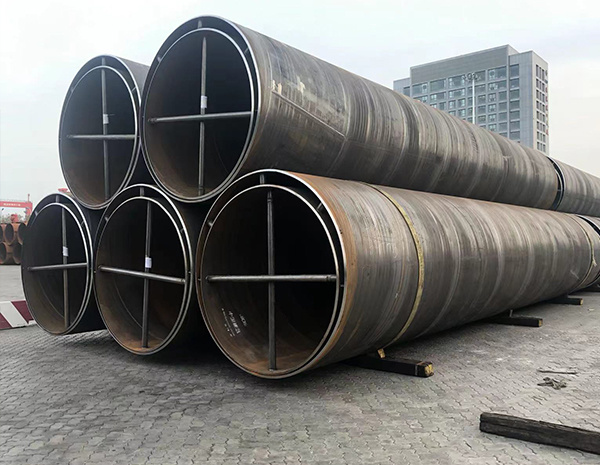

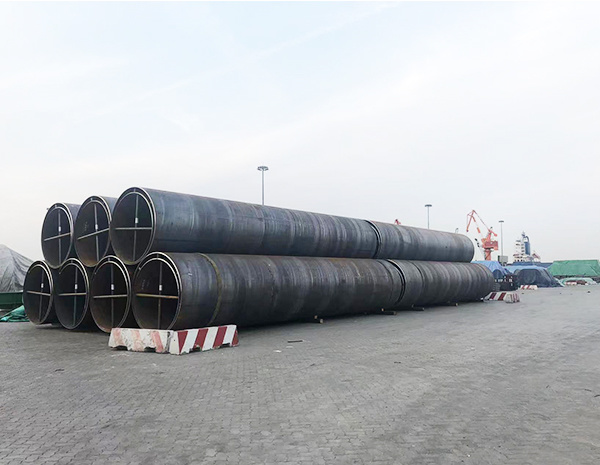

Spiral tube

Category:

Product Introduction

The ministry standard spiral steel pipe is SY/T5037-2000 (spiral submerged arc welded steel pipe for common fluid transportation pipeline). This standard is the ministry standard and GB/T9711 is the national standard. The national standard has higher requirements for steel pipes than the ministry standard.

[1]

The main production process of the ministry standard spiral steel pipe

Uncoiling-winding-leveling-butt welding-edge milling-forming-internal welding-external welding-pipe cutting-break-subsequent welding-hydraulic test

The main difference between the ministry standard spiral steel pipe and the national standard spiral steel pipe

1. Purpose (5037, steel pipe for ordinary flow transportation pipeline; 9711, steel pipe for industrial transportation)

2. Detection method

3. Various performance indicators

4. The standard national standard steel pipe does not allow Q235B material, must be pipeline steel

Main symbols for spiral steel pipe

D ----- nominal outer diameter of steel pipe mm

T ---- nominal wall thickness of steel pipe mm

M ---- steel pipe line mass kg/m

P ---- Test pressure of hydrostatic test, Mpa

S ---- Test stress of hydrostatic test Mpa

h ---- residual weld height mm

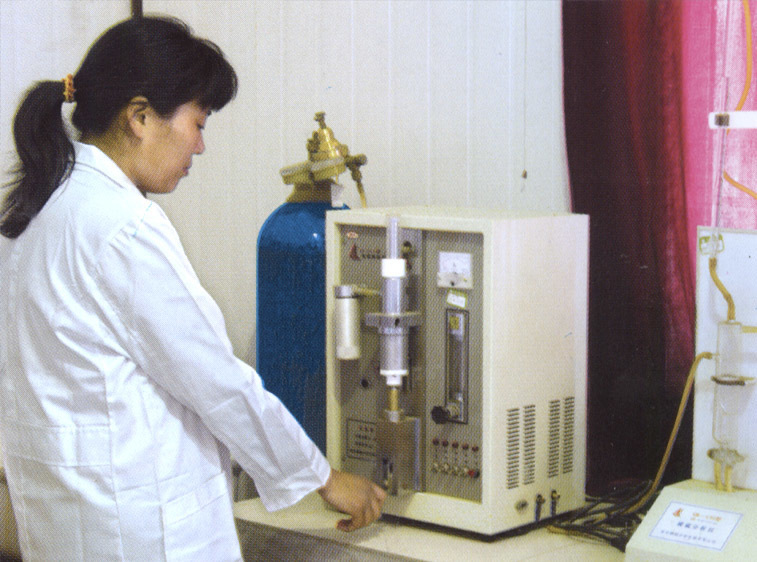

Quality Assurance

Key words:

Product Consulting

Related Products